ONLINE EXCLUSIVE:

The Who and What Behind JIT

By Mark Doman

Just-in-Time [JIT] Production depends on trained, involved employees who know they work in a process and their jobs are connected. They know that there are co-workers and/or outside suppliers ahead of them in the process (upstream) who supply them with products and/or information that they need to get their jobs done and make the process work.

They also know there are co-workers beyond them in the process (downstream) that they must supply with the required products and/or information if the process is to produce value for the customer.

In other words, they know how the business runs and they know when it is not running right. Most importantly, when they see it’s not running right, they know how to fix it and they are motivated to fix it.

Employees trained in lean know that they cannot succeed individually, but only as part of a team of employees working in a process. It sounds simple, but many employees in many companies don’t know what is happening around them and do not care. They just want to do their jobs and go home.

JIT production is the ideal. It is accomplished through a pull system where Kanbans are used by trained employees who know what they should be doing in the process as well as what other employees should be doing.

JIT production won’t work unless employees feel they are on a team and believe their success depends on their co-workers who are working along with them in the process.

It’s ironic that we absolutely understand the importance of teamwork when it comes to sports, but we stop thinking that way when we walk through the door on Monday mornings.

What is Just-in-Time Production?

JIT Production is producing the right item at the right time in the right quantity. JIT starts with the customer and looks at the production flow in reverse. It doesn’t start with “what can we make,” machine capacity or line speed; it starts with what does the customer need and works backward.

JIT is built on the foundation of standardized processes and a visual workplace.

JIT is the antithesis of the push system, which makes things based on individual machine schedules in big batches with high WIP. JIT starts with customer orders, sets the schedule in final assembly and then “pulls” what it needs from the upstream sub-processes. Companies often shy away from JIT production because it involves eliminating the “safety net” of buffers and WIP and finished goods inventory. And that can be scary. But it doesn’t have to be done in one fell swoop. We can manage the risk by planning and executing a gradual reduction in inventories as our processes are improved and become more reliable — and our employees become better trained in lean.

If our finished goods inventory is two weeks, we can work as a team to plan a reduction to one week. We stabilize and standardize the new process, and agree on when to move it down to four days, then two days, etc., until we are eventually producing exactly what the customer needs exactly when he needs it, and no more.

Companies also shy away from JIT production because it is contrary to the old conventional wisdom that the best way to run a business is to run as many parts as possible in a single run to maximize machine utilization and reduce the number of changeovers — but this ignores the customer and often results in wasted piles of defective or obsolete product that no customer needs.

The potential benefits from JIT production are significant. I recently spoke with a Ford Motor Co. plant manager who described how amazed he was at the amount of floor space that opened up when inventories were reduced, allowing them to bring additional production into the facility. Safety improved because people weren’t tripping over piles of WIP, and obsolescence costs almost disappeared.

When a quality issue was discovered, there were no longer mountains of WIP and finished inventory that needed to be reworked. This also saved money and time.

When the safety net is removed, or at least reduced significantly, the entire workforce gets much more focused on meeting the customer needs and doing things right the first time.

How Do Kanbans Fit in JIT Production?

JIT uses a simple mechanism called Kanbans to communicate what needs to be pulled through the system. Kanbans are really the voice of customers continually reminding a business what they want and when they want it. No more, no less.

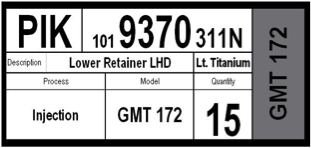

Kanbans connect and synchronize all the sub-processes in the JIT process. Kanbans are normally just pieces of brightly colored paper or cards in plastic or other types of signals that are highly visual, contain precise information (about the supplier, the customer, the part number) and notify employees in the process of what they need to do.

See the following examples that are used in the rapidly expanding Faurecia Plant in Fraser, MI:

Once the Kanban system is set up, it is amazingly simple. It greatly reduces the need for managers, schedulers and expeditors running around. Employees know exactly what to do when they see the kanban card and they do it.

Here is a simple example of a Kanban that most of us can relate to. Let’s say you order checks for your checking account and they come in a box with five packets of 50 checks each. When you pull out the final packet of 50 checks, there is a reorder form right on the top of it. You fill it out indicating the design of the check and the quantity you need. You send it back to the supplier, and by the time you finish the last packet and need more checks, you have received exactly the quantity and design you desired.

Implementing Kanban in the workplace is similar. A simple, understandable signal is sent up the chain to pull material as it is needed by the downstream customer, in exactly the quantity and specifications desired.

JIT Production à Pull System à Kanbans go a long way toward avoiding overproduction and waste, and that reduces cost and improves quality.

As Abdullah Ghanim, the Faurecia Fraser Plant FES/PSE specialist, said, “Kanban helps control overproduction, which is known as the biggest type of waste in our plants. We should only produce the right parts, in the right quantity at the right time, and Kanbans are a key lean tool to making that happen.”

JIT Production makes the process highly visible — especially the problems. It doesn’t hide problems with big piles of WIP by every machine or safety stock tucked away “just in case.” JIT forces workers to react quickly to fix the problem fast.

All of these pieces of lean — JIT, Pull, Kanbans — fit together with the help of teams of trained, committed employees, and can dramatically improve the quality, cost and lead time of the products and services you provide to your customers.

Mark S. Doman is a Pawley Professor in Lean Studies at Oakland University in the Human Resource Development Department and a member of the leadership team at the Pawley Lean Institute. Prior to joining Oakland University, he had 25 years of business experience with Ford and AT&T, where he held various executive positions in operations, human resources and legal. He has led several major organizational change initiatives throughout his career that included Lean Workouts, quality circles, TQM, process re-engineering, kaizens and corporate restructuring. He is the author of “A New Lean Paradigm in Higher Education: A Case Study.” Quality Assurance in Education, Vol. 19 No. 3, 2011 and “How Lean Ready Are You?” Target, Vol. 28 No. 2, 2012. His email address is doman@oakland.edu.