The Lean Certification Program is designed to create lean practitioners who have demonstrated a level of knowledge in specific lean tools and methods and can achieve results. This program will help partcipants grow in knowledge, experience and continuous improvement and was developed based on information and input from several key resources: Lean Applications; The Lean Certification Program in development by AME, SME, Shingo Prize; and the Toyota Learning Model.

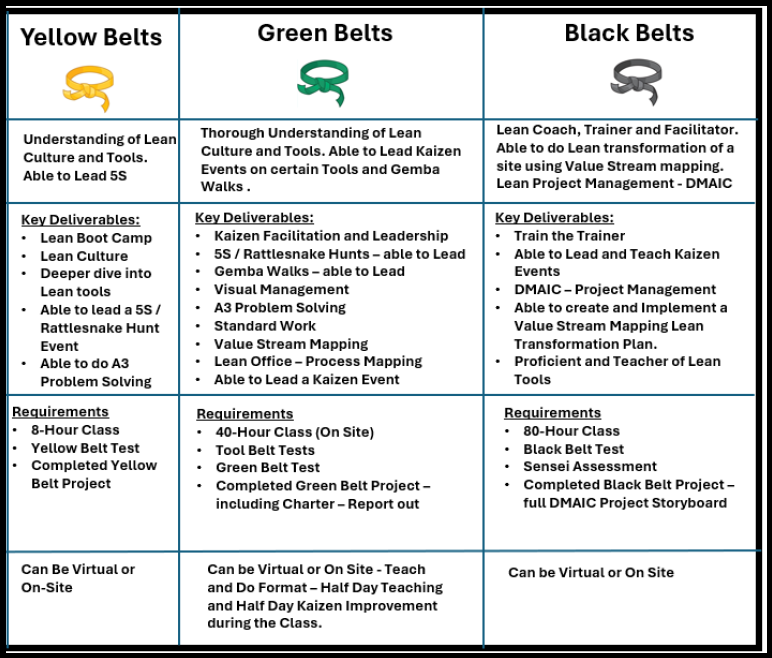

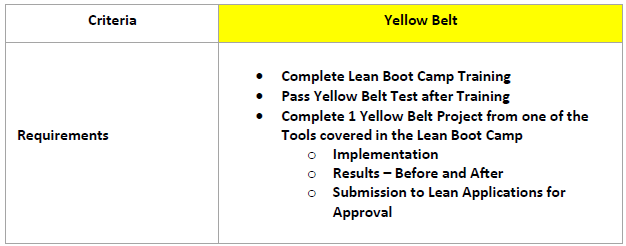

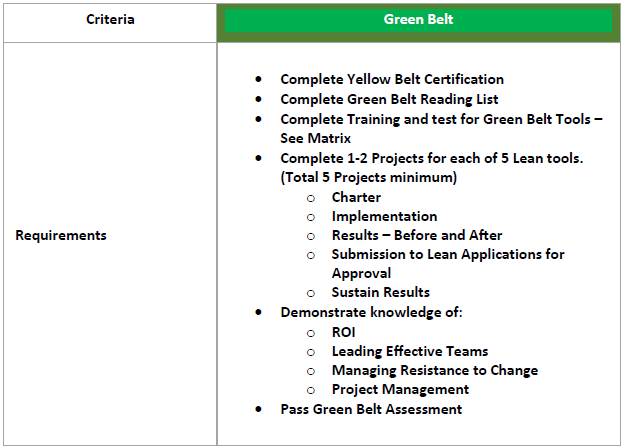

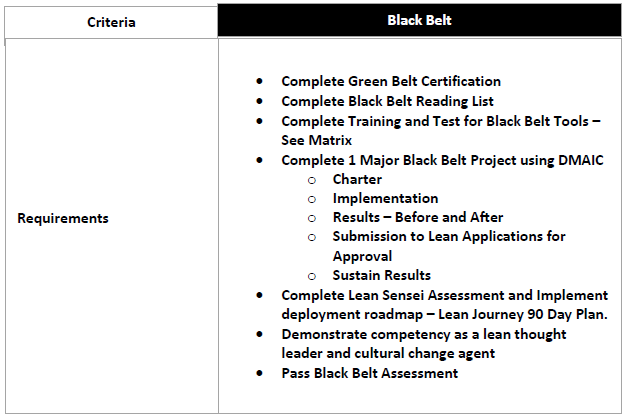

The Program is comprised of three progressive levels: Yellow Belt, Green Belt, and Black Belt. Each level requires specific criteria and levels of knowledge in three areas: basic rrequirements, leadership skills and the lean tools. You can attain Tool Belt certification in each of the lean tools as you progress in each level.

Why and how does one get certified?

The certification process is designed to be a “pull” process. Your initiative is extremely important, and we want you to get involved in this program. It is expected that employees who acquire these new skills will be able to achieve higher performance levels and greater results than those who do not. It will prepare your company for the future.

Each certification level requires completing an assessment and submitting a package to the Lean Applications office for approval. The process is based on the driver’s license model: one must not only have the knowledge of how to drive but one must also demonstrate the ability to drive.

The rigor and discipline in this certification process will ensure standard work in the deployment of lean tools and methods and their consistent application in our business. For these reasons, we plan to proceed at a pace that ensures quality over quantity of Lean Certifications.

Certification Requirements

About the presenter

Mark Preston has been driving change in manufacturing, operations, supply chain, office and sales environments for 30+ years. Previously, with TDK Electronics, he studied kaizen manufacturing techniques in Japan and held leadership positions in TDK for 11 years.

Mark Preston has been driving change in manufacturing, operations, supply chain, office and sales environments for 30+ years. Previously, with TDK Electronics, he studied kaizen manufacturing techniques in Japan and held leadership positions in TDK for 11 years.

After TDK, he held various executive positions at Respironics Inc for eight years, leading operations and structured global sourcing, creating the 13-week supplier development program, and holding the role of director of operations for Asthma and Allergy.

After Respironics, Preston was the director of acuity business system at Acuity Brands Lighting (Lithonia Lighting) and was promoted to vice president of supplier development and operational excellence. Preston also worked with Kohler as the global director of operational excellence in 2022.

Preston started his own company, Lean Applications, and has worked with companies globally to drive passion for improvement by focusing on people, processes, and purpose, for more than nine years.

Key accomplishments

- Mark Preston has been a keynote speaker for organizations across the U.S., including CME, AME, YPO, APICS, CSCMP, MODEX, CME, SCOPE and IMPACT Manufacturing.

- He published his first book, “Southern Sensei” in 2017.

- He created the “AME (Association of Manufacturing Excellence) Lean Sensei,” which helps companies evaluate themselves on their lean journey toward excellence.

Four questions with the presenter: Mark Preston, Lean Applications LLC

1. Participants will engage in the Rattlesnake Hunt exercise — can you give us a sneak peek at what that is and why it’s effective?

How do you combine employee engagement, learning to see, elimination of waste and creation of pull into your lean journey? Go on a Snake Hunt! A snake will bite you if you see it, bite you if you hear it, and if you are around it long enough, it will bite you! Think of them as safety snakes, quality snakes, 5S or something that might turn off the customer. This Kaizen event will, without a doubt, become one of your winning best practices. One of the first steps toward educating associates in lean is to help them see and identify waste. By seeing waste in a visual and competitive way, associates develop a much easier way to remember what they need to be looking for.

2. Who would benefit most from attending this workshop?

I have not seen anyone not benefit from this workshop. Executives, leaders, technicians and all associates have benefited. I have certified more than 3,500 Yellow Belts in manufacturing, healthcare, service and office environments.

3. What would you say to someone on the fence about attending this certification workshop?

This workshop is rated as a top workshop that AME offers. Not only is it a fun educational experience, but every participant leaves with practical knowledge that they can directly implement within their office, service and manufacturing sites.

4. What excites you most about teaching this workshop?

It is exciting for me to see light bulbs come on in the eyes of everyone that participates. They realize that lean is not complicated and not just a tool. Lean pulls strategy, engagement, problem-solving and communication together when you understand how culture works hand-in-hand with creative ways to implement sustainable actions.

Register today!

Are you ready to drive continuous improvement and eliminate waste within your organization? Through engaging discussions, real-world case studies and interactive exercises, you’ll develop a problem-solving mindset and learn how to hunt down operational inefficiencies before they impact your bottom line.