There is a critical but forgotten lesson in problem-solving to be learned by reflecting on how mission control and the three astronauts aboard the 1970 Apollo 13 moon mission responded when an oxygen tank suddenly ruptured. They didn’t take out an 11-by-17 sheet to begin an A3 to identify the root cause of the rupture; the commander didn’t pull out a five-question kata card to coach the crew; and no one collected a 30-part data sample for a six sigma analysis. They first invoked good troubleshooting routines to manage the abnormal situation. Sometimes this style of response is part of initial problem-solving activity and a necessary part of the process. The Apollo 13 crew and mission control were faced suddenly with a loss of primary propulsion systems, oxygen, potable water, food, heat, a dangerous buildup of CO2 and other abnormalities. In 1995, the movie “Apollo 13,” which popularized the familiar quote “Houston, we have a problem,” depicted the rapid-response style of problem solving that heroically got the crew home safely. The crew and NASA support staff jointly worked around the clock to come up with temporary solutions to different problems to get the astronauts home. Interestingly, the movie did not really depict the actual problem-solving investigation methods or root cause of the incident. This was determined much later after the crew safely returned home and probably did not make for good Hollywood effect. (Note: In case you are interested in what the movie very briefly mentioned but did not depict, here is a link to the basic findings and conclusions https://go.nasa.gov/2qkp5Lf)

The Apollo 13 crew and mission control were faced suddenly with a loss of primary propulsion systems, oxygen, potable water, food, heat, a dangerous buildup of CO2 and other abnormalities. In 1995, the movie “Apollo 13,” which popularized the familiar quote “Houston, we have a problem,” depicted the rapid-response style of problem solving that heroically got the crew home safely. The crew and NASA support staff jointly worked around the clock to come up with temporary solutions to different problems to get the astronauts home. Interestingly, the movie did not really depict the actual problem-solving investigation methods or root cause of the incident. This was determined much later after the crew safely returned home and probably did not make for good Hollywood effect. (Note: In case you are interested in what the movie very briefly mentioned but did not depict, here is a link to the basic findings and conclusions https://go.nasa.gov/2qkp5Lf)

The style of problem depicted in the movie is what I call a Type 1 or very good Troubleshooting problem. The crew and control team rapidly dealt with the most pressing issues in the best ways they could under the circumstances. They did not accomplish the mission of landing on the moon or determine the cause of the tank rupture during the mission, but they overcame all the obstacles preventing the crew from returning home safely.

We probably will never have to deal with an oxygen tank rupturing while on a spacecraft 205,000 miles from earth, but we all face problems requiring a quick response on a daily basis. Upset customers, difficult software, malfunctioning equipment or sudden pain, for example. However, most companies I see hemorrhage abnormalities daily because they are fairly poor troubleshooters. They tend to believe they are already great at troubleshooting but often this is not the case. There are levels of ability to consider when even discussing troubleshooting. For example, even with a fire, you can have weak or slow response teams. Or you can have very good and highly proficient first responders. And then you can have world-class experts like “Hot Shot” teams that head into trouble areas where other equipment and people simply cannot go.

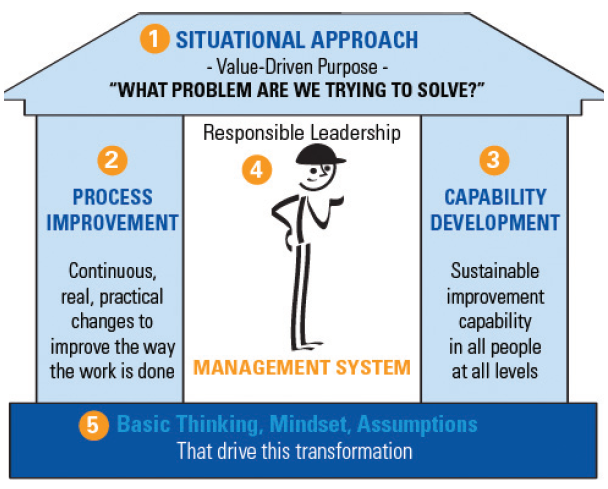

I’ve learned from working with various organizations, brilliant scientists at Scandia National Laboratories and world-class problem solvers at Toyota’s Kamigo Engine Plant that problem solving, like leadership, is situational. In other words, one approach does not fit all, nor produce optimal results. In the lean transformation model (see diagram above), problem solving is step 1 and labeled as situational. The question is posed, “What problem are we trying to solve?”

An expert problem-solving coach or manager looks at problems from different angles. Retired former Toyota engineer and expert problem solver Tomoo “Tom” Harada used to make me solve machining problems several different ways, e.g., cutting conditions, tooling, fixturing and materials angle as a way to have me develop thinking skills. For Tom’s generation in Toyota under Taiichi Ohno, a person who could solve a problem multiple ways was better than a person who only knew one way. In my experience, I find that a framework of four types covers most business problems we need to consider. Let’s review all four, then take a closer look at the often neglected and underemphasized Type 1.

Understanding the 4 types of problem solving

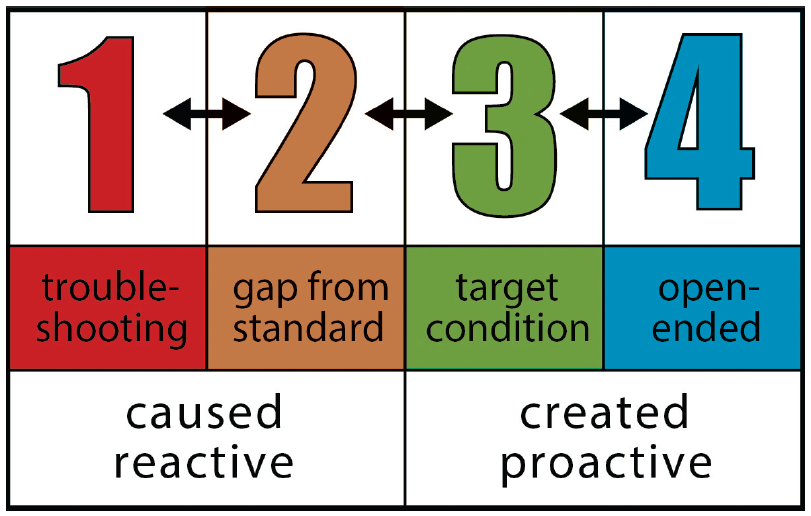

The 4 Types of Problem Solving: Many companies distinguish between two basic types of problems: caused problems /reactive responses versus created problems/proactive responses. The Four Types framework breaks these down further.

Type 1 or Troubleshooting deals with rapid responses and fixing problems as quickly as possible to manage the daily situation. It is not ideal by any means but, as I’ll explain later in greater detail, it is often necessary. As in the Apollo 13 example, sometimes this reality is forced upon a team, and you have to respond accordingly in a very short time window.

Type 2 or Gap-from-Standard is the more preferred and effective problem- solving approach. We frame the issue in greater detail, set a goal, drill down to a root cause, identify countermeasures to prevent recurrence, check results, follow up and ideally eliminate the problem entirely. The difficulty with Type 2 is that sometimes it can take a while because the problem is complex requiring greater analysis. (In Type 2 fashion, NASA eventually traced the root cause of the oxygen tank rupture to the installation of a wrong thermostat relay and implemented a countermeasure to prevent recurrence.)

Types 3 and 4, Target Condition and Open-Ended, respectively, involve higher degrees of creativity and go beyond traditional problem-solving notions. With these two, there is no gap-from-standard condition requirement. In fact, things might be running along just great. But next year, for example, we want to raise the bar. Customers expect improvement and competitors will drive toward it as well. In the short term, say, under one year, we can incrementally improve existing products, processes and people relation areas with creativity. This is the hallmark of true kaizen in Japanese: Produce a better result by examining current methods to come up with a better way. Type 4 takes this to an extreme by allowing a total open-ended approach and creating entirely new systems, products, processes, etc., in a more radical way. Type 4 is pure open-ended innovation. While breakthroughs are less common they are usually more valuable. Without enough innovation successes, companies eventually become obsolete or get bypassed.

These four types are essentially the patterns I personally observed from my mentors and watching many experts over many years. One of them, Isao Kato, who was a major force in the development of problem-solving training at Toyota for decades, urged me to look at every problem from multiple angles, not just one. He often invoked the phrase “kata ni hamaranai,” a common Japanese expression that means “not getting trapped into one way or method.”

How to manage daily abnormalities

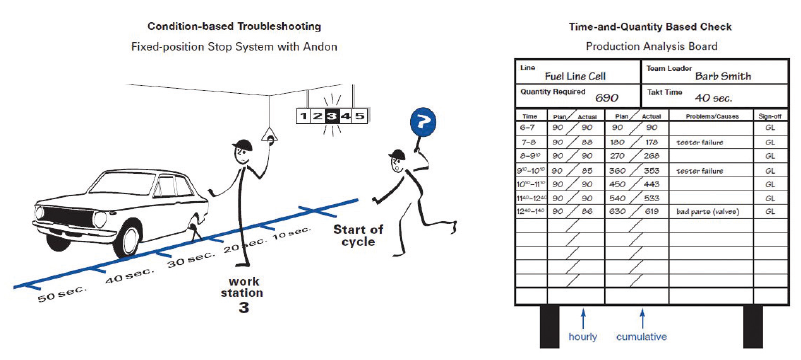

Where Troubleshooting Works: In the Toyota Production System, troubleshooting is used to solve smaller issues that can be solved at the front line, such as when operators identify abnormal conditions on the line and call for help, or in time-based tracking and hourly quantity checks that compare actual to planned production.

In a perfect world, we wouldn’t need Type 1 Troubleshooting routines. But the world is not perfect. Resources are finite and very much constrained in the short term. For example, large Toyota facilities often have more than 5,000 employees operating across multiple shifts. During a new launch period, such a facility could have 10,000 andon calls for help in a 24-hour period. The question is how do you to manage that volume of calls and achieve the desired daily results for safety, quality, delivery, productivity and cost?

The answer is that over years of developing the Toyota Production System (TPS), the company, created an internal system of triage. Most of the problems are broken down into smaller issues and solved at the front lines. Training issues, minor stops, small quality concerns and delays, are immediately addressed on the job by the worker, supervisor and first-line support responders from functions such as quality, maintenance, engineering, etc. Problems are surfaced by the condition and a call for help, or by time-based tracking and hourly quantity checks. Some problems are corrected in minutes, some in hours.

Everyone is exposed to this system of thinking their first day on the job. In direct production areas, the goals are usually easy to establish and track on the appropriate frequency. Low-volume operations, for example, might not need the same frequency of checking as a high-volume area. Support departments are service providers to the main production area and help them attain their goals while attaining their own objectives.

In some cases, you must get creative and figure out what constitutes an abnormal condition or inadequate result of work for your given time period. Errors in entering purchase orders, ordering spare parts, receiving customer complaints or advancing project type of work all have different patterns associated with them. One size does not fit all. At the heart of the issue, we strive to surface if there was an unsafe act, abnormal condition, incorrect result or any similar type of issue that deserves attention. If so, we want to surface it quickly for resolution.

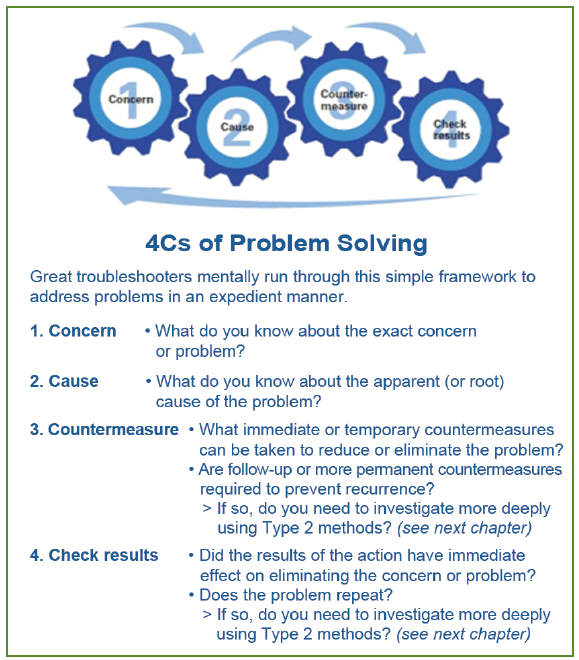

At the basis of Type 1 Troubleshooting is the 4C Thinking Pattern of 1) Concern, 2) Cause, 3) Countermeasure and 4) Check Results. (You can substitute Corrective Actions for Countermeasure if that is your corporate language.) The key point is to have a verbal routine of problem solving you can quickly adhere to without much in the way of documentation. Most Type 1 andon-initiated problems in Toyota are solved verbally.

In many instances, this is all you need to address a basic problem. I would not recommend it for recurring problems, critical injuries, customer complaints or other serious issues. For those, I recommend the more traditional multi-step methods that have been developed over the years by different parties. The Toyota 8-Step Model is an example.

In many instances, this is all you need to address a basic problem. I would not recommend it for recurring problems, critical injuries, customer complaints or other serious issues. For those, I recommend the more traditional multi-step methods that have been developed over the years by different parties. The Toyota 8-Step Model is an example.

Some organizations like to claim they are already proficient at Type 1 issues. The real problem, they claim, is their inability to solve Type 2 problems to fix the big hitters. And almost every company I see does need to improve its skills in Type 2 problem-solving routines. However, most organizations are also inadequate when it comes to Type 1 routines. To prove it, I usually just need to collect some data on Type 1 problems at the company over a 24-hour period, then have the organization grade its response in terms of 1 to 5 (low to high). Typically, they score many more response rankings of 1, 2 or 3 than they expected. We are not as excellent at this style as we tend to believe.

Still, other individuals put down all troubleshooting as “bandaiding” because it doesn’t always get to the ultimate or deepest root cause. This goes back to my earlier point about fighting fires. You can be bad at it, good at it or an expert Hot Shot. I would suggest striving for the latter two levels. Sometimes you won’t get to the root cause during the first day or even first week of investigation still think about how to first get back to standard as quickly, correctly and safely as possible.

The troubleshooting I’m referring to is also very much like the concept of triage on a battlefield or hospital. Many injuries or problems abound and not all of them are equal. Some form of triage is essential. In Toyota, the most critical issues get the most attention; less critical ones get less. Some are pursued more deeply with 5-Why thinking (ideally all of them would be), but many are dealt with in a safe and expedient manner to get safely back on track.

For example, let’s say a tool snaps; you want to replace it within a cycle. If it repeats a second time or third time, you would investigate more deeply. But a one-time occurrence could be due to a faulty tool or a hard spot on the materials. It’s the quick troubleshooting that gets you to the next cycle.

The situation (occurrence, frequency or intensity) dictates if we need to dig deeper. Other examples include unjamming a machine, rebooting software or turning your Internet router or smartphone off to resolve some type of connectivity issue. Sometimes a short-term fix is allowable under the circumstances.

Effective troubleshooting also requires some spirit of what I call “win the minute to win the hour; win the hour to win the shift; win the shift to win the day.” It adds up to a good month, a good quarter and a good year, but you better win those minutes. Of course, you still have to deal with Type 2, Type 3 and Type 4 problems. I am simply also pointing out the often-neglected role of what I refer to as Type 1 responses.

Don’t trivialize troubleshooting

Nothing ever goes 100 percent according to plan. There always are and always will be problems to find and solve. Type 1 problems typically arise on their own; you don’t always have to search for them. They find you in the form of customer complaints, work stoppages, information errors, abnormal conditions, pain or other forms of disruption. Sometimes they are hidden. All of these abnormalities usually need some type of immediate response—troubleshooting.

True, some troubleshooting routines deal with symptoms, not underlying causes. But it is important to recognize that rapid reactive problem solving still often needs to occur. It shouldn’t be trivialized or ignored. My personal three emergency room visits over the past 10 years have all resolved serious pain issues (kidney stones and diverticulitis) but did not really address the root cause. Even quality troubleshooting will not lead to an ideal state, but it can satisfy immediate needs, protect the customer, and buy vital time to delve deeper into critical details to search out the root cause. Because sometimes, before you can meet to brainstorm; draw a value stream map; or ask “why” five times, you just have to unjam the machine, put out the file, make the daily goal, or make it safely back to earth like Apollo 13.

Art Smalley learned problem solving at the historic Toyota Kamigo Engine Plant from Tomoo Harada, who led maintenance activities that created the stability for Taiichi Ohno’s innovations in flow production to succeed. When he isn’t practicing martial arts or relaxing in his woodworking shop, Art shares his expertise in lean management, problem solving and leadership through his company, Art of Lean, and his latest book “Four Types of Problems.” This article originally appeared in the Spring 2019 issue of Target magazine. Don't miss problem solving workshops and sessions at AME Chicago 2019.