by Jeremiah Davis

It’s a scenario many are familiar with: the invasion of the “Lean Team.” They invade your work spaces and follow you around with clip boards and stop watches. And many feel the same way about them: they don’t really know anything about our jobs, not the important details at least. But they want to make changes anyway. We wish they would just leave us alone!

Sound familiar?

The world around us is changing. The lean philosophy (essentially “making obvious what adds value by reducing everything else”) is gaining more recognition. It’s no longer simply an idea limited to the manufacturing world; more companies and industries are implementing lean teams. These lean teams are created so that their respective members become the subject experts, enabling them to become a vital element in the success of their company.

Theoretically, these teams are supposed to understand the tools and how to apply them. But sometimes there is a missing element as companies try to implement the lean philosophy: a scientific approach. All too often, lean proponents will excitedly grasp onto the idea and simply go around looking for things to improve without a clear approach to solving problems. Without employing a good scientific approach though, they never accomplish much more than mere reorganization.

I sometimes wonder if people avoid using a scientific approach out of lack of confidence (i.e. fear) in their ability to implement it effectively. Some may say to themselves, “I’m not a scientist; that kind of thing is beyond me.” They respond like the old cliché of an old dog who can’t learn a new trick.

I contend that we shouldn’t limit ourselves by labeling what we are and are not, though. Scientific thinking is not just for scientists, nor is it a scary thing that we should fear. The scientific method is simply a way of thinking to help each of us and our companies be more successful. We need to collect vital information and should use it to try the experiments that lead to new ideas and breakthroughs.

Aristotle said, “All men by nature desire to know.” This starts when we are small children. We start our lives being curious and trying to understand all the new things around us. We naturally think scientifically.

With the introduction of Improvement Kata, we now have a structured way to teach the scientific mindset required of a true expert in lean thinking. And teaching new experts is not a process that should start once we enter the professional world, but much sooner. To make the lean philosophy truly effective in the future of our world, we need to create a new paradigm. So how do we do that?

Video link: https://youtu.be/bZfeBYE6QEk

With the continuing growth of lean thinking, it is more important than ever that our children (no matter what they ultimately choose as a profession) start learning about lean as kids. This will create a culture where the first paragraph of this article could no longer be how people feel. The Improvement Kata is the tool we need to use to achieve that goal.

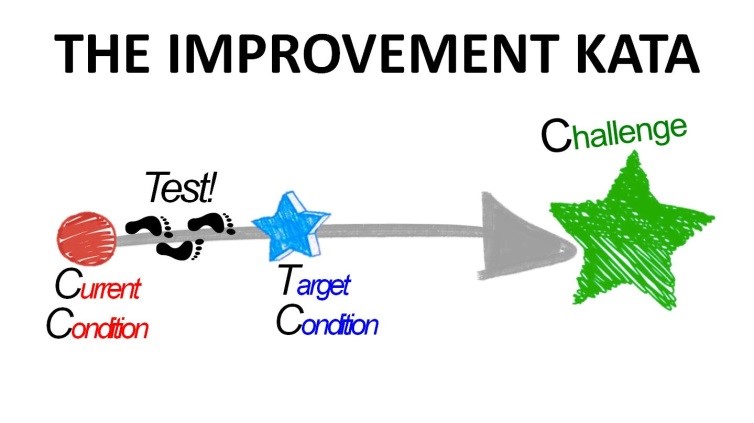

The Improvement Kata follows 4 steps:

1. Set the direction. This is setting a challenge that you are not sure how you are going to achieve but by getting there great things will happen. This is typically a goal to be achieved in one to three years.

2. Collect measurable data and analyze the current state you are in.

3. Using the data you have collected, pick the first desired target condition that you want to work toward. This is a smaller (e.g. two weeks out) goal that will get you closer to your challenge.

4. Identify obstacles and experiment toward making the target condition in Step 3 a reality.

Video Link: https://youtu.be/NYQGjNLc53Y

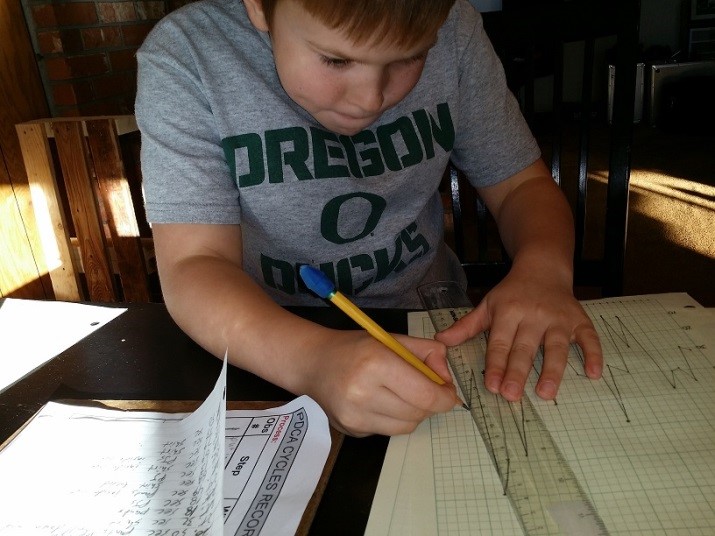

This is the process I am implementing in my own home. I set challenges for my kids and they work toward reaching them through collecting data and then experimenting toward a future state. By encouraging my own children to follow these four steps, they have the opportunity to practice a scientific routine that will become second nature to them over time while working to improve the day-to-day processes they currently face.

When we started, my daughter was 14; the three smaller children (then five-, six-, and seven-years-old respectively) were not practicing as learners but still helped with the experiments.

Our biggest problem area was the kitchen. It was connected to the dining room and a central area of the house where the most time was spent. I set a challenge that no matter what it would never take longer than five minutes to clean the area.

When we began, my daughter could take up to 40 minutes to clean the kitchen. As we experimented, she was able to reduce that time to around the 10 minute range with more control. In the earlier practice they would 5S an area and then test that by checking to see how it improved their times. Then they would repeat with another area and see what effect it had.

The next year, the younger kids started working toward the challenge of only taking five minutes to clean their bedrooms (no matter what). This led to some surprising results as they weeded through their books, toys, and clothing, eventually eliminating around 40% of what they owned. Though clean up times have improved quite a lot they have not yet achieved the challenge time. But they continue to get closer, and it is that continual effort to improve that is most important for them at this point.

As the kids have practiced to reach their challenges, I’ve seen them implementing the scientific mindset in other areas when they see something needs improved.

Delia (now 16) has been applying the Improvement Kata to her school work.

Hailey (9) is playing softball for the first time and wants to become the MVP of the team. She started out with a batting average of .080 and her fielding skills were showing slightly better but similar metrics. Through experimentation she is now batting an .850 and is one of the best fielders on the team. If she isn’t the MVP by the end of the year I would have to say she has at least shown the most growth on the team.

Aidan (7) has ADHD and has struggled with focusing on simple tasks such as putting on his shoes (it can take him anywhere from between 40 seconds to 12 minutes to get them on and tied.) He set a challenge to never have it take more than 1 minute. He identified the obstacles that were in the way of him achieving that and experimented toward making it the reality it is today.

Bradley (8) has used the approach for several things; one of the more interesting applications involves his skateboarding. He will try a trick and then talk to me about what he thought went wrong. He identifies what he feels he needs to change or fix and tells me, “next time I will try this and I think I will get it.” If that doesn’t work, he will continue to come back and discuss what didn’t work and what he will adjust next time to get the result he is looking for. Eventually he will have an “ah hah” moment and realize exactly what he needs to do to solve the problem (e.g.“oh, my feet need to be here on the board and I have to be moving much faster so I don’t fall forward”). When he makes these discoveries, I make sure to ask “can you repeat the trick then since you know what you have to do,” which reinforces the results of using a scientific approach effectively. By applying what he has learned through analysis and experimentation, he is able to go back and land the new trick again and again.

Recently, we were experimenting with a Kata Learner class at work. During the session, I observed a breakdown in the way we were communicating a section of the training. Everyone seemed to be lost and struggling through the exercise. Bradley had just learned this useful tool for understanding that particular condition and so I thought he and I could create a useful video that might help in the class (after all, if an eight-year-old can do it then an adult should have no problem picking it up). The video was successful and resulted in a lot less confusion in this section of the class.

Bradley and I had so much fun that we decided we should make a whole series of helpful training videos. The kids and I created a YouTube page called “Kata at Home” where we post helpful coaching videos that any company could use in their training. If kids can do it, then working professionals should be able to also.

Video Link: https://youtu.be/NnaQ1Zha0eg

Not all that long ago my wife and I were talking about how we measure our parenting. Our measurement criteria are different. She measures success based on what she sees now (e.g. their behavior and happiness), the way I measure doesn’t show me such immediate results. I will not know if I’m a successful parent until a little further down the road. I am focused on their development. Neither of us are right or wrong, (actually I think her thoughts and mine are a very nice balance of parenting), but I do know that by having the kids practice this scientific improvement mindset they will develop the skills in life needed that will give them advantages in their adult lives.

If you are interested in giving your kids a head start in the world of true lean thinking, here are several resources you can check out:

• Search the YouTube channel “Kata at Home” and subscribe to the page. We have several helpful videos in the works.

• www.katatogrow.com is a great website for finding additional information, videos, and training exercises.

Jeremiah Davis works for A-dec, Inc. (an Oregon-based manufacturer of dental equipment – chairs, cabinets, delivery systems and dental lights) as a Manufacturing Engineer (and Kata Coach) with a primary focus on coaching and training. He started his lean journey in 1998 with Climax Portable Machine Tools and has been practicing Improvement Kata since 2011. Since then, he has had the opportunity to develop and lead training programs for dozens of individuals. Though he knows he is still in the early stages of learning, he has ignited a new culture and mindset change that continues to grow across A-dec. Jeremiah 1st and 2nd coaches up to 39 coaching cycles a day; steadfastly driving the belief that struggles and obstacles are just opportunities to learn and grow. Kata has become a perfect match for him. His curious nature has served to expose gaps within processes. His innovative personality drives him to develop unique solutions to address those gaps. The Improvement and Coaching Kata patterns are engrained in Jeremiah and he has successfully transferred this thinking to his home life. His story and use of Kata caught the attention of former AME Conference Keynote speaker and Toyota Kata author Mike Rother.