San Diego is widely known as a hub of innovation. That’s just one of the many reasons AME chose San Diego to host its 2018 International Conference. This year AME San Diego 2018 conference attendees can go and see operational excellence firsthand at more than 40 local best practice tours. Tours committee co-chair Jerry Wright spoke with us about what continuous improvement practitioners can expect to see this fall and how AME organized its 2018 tour line up in a city teeming with lean.

San Diego is widely known as a hub of innovation. How does a local facility become a tour site at the AME International Conference?

Jerry Wright: The conference tours committee will start by visiting the tour site to see what the attendees will be seeing at the conference. What we’re typically looking for is alignment with the AME Excellence Award criteria. We’re looking for what we call Pearls of Excellence—something that a company does well that can be shared and that our attendees can learn from. An example of a pearl might be a great leader standard work process, where everyone is organized, with a daily gemba walk, operators from different functional areas report out to the team and indicate status. Another pearl we often look for is a great material replenishment and stocking program that follows the principles of the Toyota production system, or a Kanban two-bin type of system that allows them to have virtually no shortages and constant flow to the production floor.

What AME San Diego 2018 tour sites do you think attendees will be most excited about?

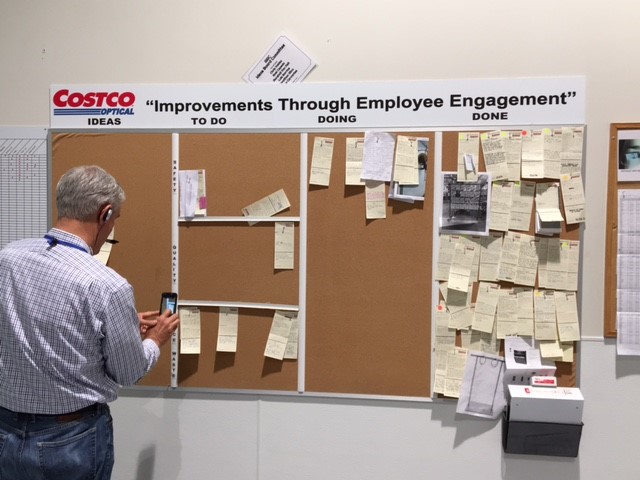

JW: Costco will offer two tours during conference week that will likely fill up very quickly. Attendees can visit both the Costco Optical Lab, which processes 11,000 glasses every day, and Costco Wholesale Industries; Costco’s packaging facility here in San Diego services half of the Costco world—all the western U.S. and the Pacific Rim. Costco’s kaizen (idea) boards are fantastic, and a great example of a best practice that I would consider a “pearl."

JW: Costco will offer two tours during conference week that will likely fill up very quickly. Attendees can visit both the Costco Optical Lab, which processes 11,000 glasses every day, and Costco Wholesale Industries; Costco’s packaging facility here in San Diego services half of the Costco world—all the western U.S. and the Pacific Rim. Costco’s kaizen (idea) boards are fantastic, and a great example of a best practice that I would consider a “pearl."

All the sites have something different to offer. Another site I think that folks are going to be really excited about is General Atomics, for those attendees who are U.S. citizens. They manufacture Unmanned Aerial Vehicles (UAVs) and related mission systems for the military. They are a fantastic vertically-integrated operation. Also, it’s a neat process by which they manufacture these vehicles.

Another operation that I think is particularly interesting is HM Electronics. They just moved into a brand-new facility in Carlsbad, and they do lean from soup to nuts, meaning they’re following all the different criteria that we would see in an AME Excellence Award recipient—from leader standard work, Kanban, kaizen events, employee idea system, cellular flow, just-in-time manufacturing, and more. We will also be touring Illumina. Illumina is the largest player in the genetic sequencing market; they support genetics-testing services like 23andMe and Ancestry.com. They have an amazing campus and some great practices in place there. They started their journey within the last few years but they’re making a ton of progress in a heavily regulated and interesting environment.

We also have tour hosts in both Tijuana and Tecate, which are only about a half-hour drive from downtown San Diego. You need a passport for these tours, but it’s just a day trip, and this will be a neat experience for attendees. One of those sites is Ossür Medical, which is in Tijuana. They have great strategic policy deployment and a very visual factory with lots of cellular processes. Over in Tecate, is Broan Nutone. Broan Building Products has a full-on, one-piece flow, pull-based line for sheet metal products that people just look at and walk away saying, “wow, these guys really get it.”

Will attendees tour companies that are outside the manufacturing industry?

JW: Absolutely. The United States Postal Service has a Lean Six Sigma program that they’ve been working on since 2007 following a push to reduce cost in the postal system. We’re going to tour their Margaret L. Sellers Processing and Distribution Center in San Diego, which sorts mail 24-hours a day and uses visual management, gemba boards, and other lean and six sigma tools.

The city of San Diego and the City of Chula Vista are also going to be tour hosts this year, and highlighting how they run lean in their operations, whether they’re managing the motor fleet for the Chulla Vista police department or handling road repairs and graffiti. It will be beneficial for attendees to see lean in these service-based sites.

How does the tours committee use the AME Lean Sensei app?

JW: The AME Lean Sensei is an app and Excel tool that helps companies benchmark their progress, and see how they rank next to distinguished AME Excellence Award recipients. The AME Lean Sensei and the AME Excellence Award are essentially woven together—one feeds the other. Companies that apply for the award use the AME Lean Sensei to do so. We also use the AME Lean Sensei at prospective tour sites to find those Pearls of Excellence. All the members of the tours committee are all very well-versed in the AME Lean Sensei. We are all AME Excellence Award Examiners and so it’s easy for us to walk in and see if the company is going to fit the criteria or not. Some of the companies may only hit four out of the twelve criteria and others will hit 11 out of the 12 criteria at a good level. But, if the companies have something that we think attendees will benefit from, we absolutely want to include them. Even if they’re not ready to be an AME Excellence Award recipient, they’re still on the journey and that’s important to see too.

To register for the AME 2018 International Conference, visit ame.org/SanDiego today. To learn more about the AME Lean Sensei app and excel tool or to download, visit ame.org/LeanSensei.