While planning strategies for continuous improvement, it is important to maintain awareness of the building in which the people and equipment are housed. The roof, for instance, has a direct impact on the amount of energy consumed and the ability to curb waste through emerging technologies, such as solar power systems.

While metal roofs are not a new concept, many developers had a tendency to rely on asphalt roofs. They are especially common in industrial parks where developers erected cheap structures to quickly flip for profit. Today this is changing with the increasing movement toward greener building, said Englert Marketing Director Mitchell Gaber. Englert constructs commercial roofing and gutter systems made of metal. He said customers today are more informed and demand higher quality products. The government also has enacted building codes to prevent developers from relying on the cheapest solutions. As a result, the number of buildings with metal rooftops is multiplying.

Metal roofs require less maintenance and can be retrofit directly on top of existing flat roofs without interrupting business. Incorporating polyurethane products and paint, they offer a weather-tight cover that justifies the initial cost. With the building warmer in the winter and cooler in the summer, savings on energy bills can be expected.

The true advantages of metal roofing systems are its versatility and ability to support new technology. Every time a satellite dish or antenna is installed on top of an asphalt top, holes must be drilled into the surface, which jeopardizes the building’s integrity. This creates the potential for leakage and often voids a warranty. Metal roofs with standing seams only require clamps. These rooftops also survive much longer, making them a better foundation for other technologies. Whereas, installing a solar power system on top of an asphalt roof would be self defeating. The panels would outlive the roof, and it would be a costly procedure to remove and reinstall them when the roof is repaired, said South Coast Solar COO Scott Oman.

Solar Power

Solar power and metal roofs have become the perfect marriage, explained Robert Zabcik director of research and development for the metal roof company NCI Building Systems. The standing seam of a metal roof has eliminated the need for a railing system that would be needed to mount solar panels to an asphalt surface. Fewer parts translate into cheaper installations, and partnerships are forming between solar and roofing companies that benefit each industry and the end users. For example, NCI Building Systems receives deals on solar technologies in exchange for access to his database. As a result, solar companies can go straight for the rooftops that offer the easiest installation.

Solar Water Heaters

Solar panels also collect the energy needed to employ roof-mounted water heating systems. Instead of generating electricity, the solar panel conducts heat that is moved into a tubing system filled with propylene glycol. This heated chemical remains in a closed loop that passed through a heat exchanger, usually comprised of copper tubes, Zabcik said. The tubing makes contact with the water inside a tank that drains back to the building’s gas water heater. Since the water has been preheated on the roof, less energy is needed to achieve the desired temperature.

Sunshine

While solar technologies have made significant strides the past several years, a more efficient use of the sun is to simply let it shine. Skylights incorporate well with metal rooftops because companies such as NCI Building Systems coordinate their specs with those of the venders. These introduce light into a building to reduce the amount of waste generated through electrical lighting systems. Most skylights consist of a frosted glass that can diffuse light across large areas. Often they include lever-controlled shading systems mounted below.

Light-transmitting panels are less expensive and integrate directly with the roofing system. However, because they are flat, they do not gather as much light as skylights, which are dome-shaped and elevated. Another viable option is the solar tube, a cylinder lined with reflective material collects and redirects natural light.

Rain Water Retention

With so much invested on one roof, it is essential to maintain proper water drainage to protect equipment. Metal roofs offer slicker surfaces to provide faster, unrestricted water runoff, which is redirected to gutters. This too can be converted into an investment, as water moves through filters and into rain-water harvesting systems. Englert recently reduced its dependency on municipal water by redirecting rainwater to cool its paint line.

As operating costs increase with the price of energy, it is a best practice to tap into what comes freely. Rainy and sunny days are guaranteed, but building owners must first invest in the technology to extract the resource. This requires a sturdy foundation on which to build, and metal has proven itself solid.

While a growing population believes in the benefit of solar technology, it is still difficult to accurately estimate the return on investment.

Most dealers tell doomsday tales — often substantiated — of the ever-rising cost of monthly electric bills, making a fast ROI seem more likely. South Coast Solar COO Scott Oman said a 2.5 percent annual increase is a conservative national average. He said without taking this into account, solar technology would be a lot less appealing to his customers. However, the panels are guaranteed to produce 80 percent of their intended value for 25 years, and he indicated the theoretical life is 35 to 40 years.

Climate also plays a critical role. Panels in Tucson generate more electricity than those in Seattle. However, available tax incentives and grants for investing in the technology are not awarded equally in every state. The cost of electricity also varies per region, as do the utility companies’ methods for calculating monthly bills.

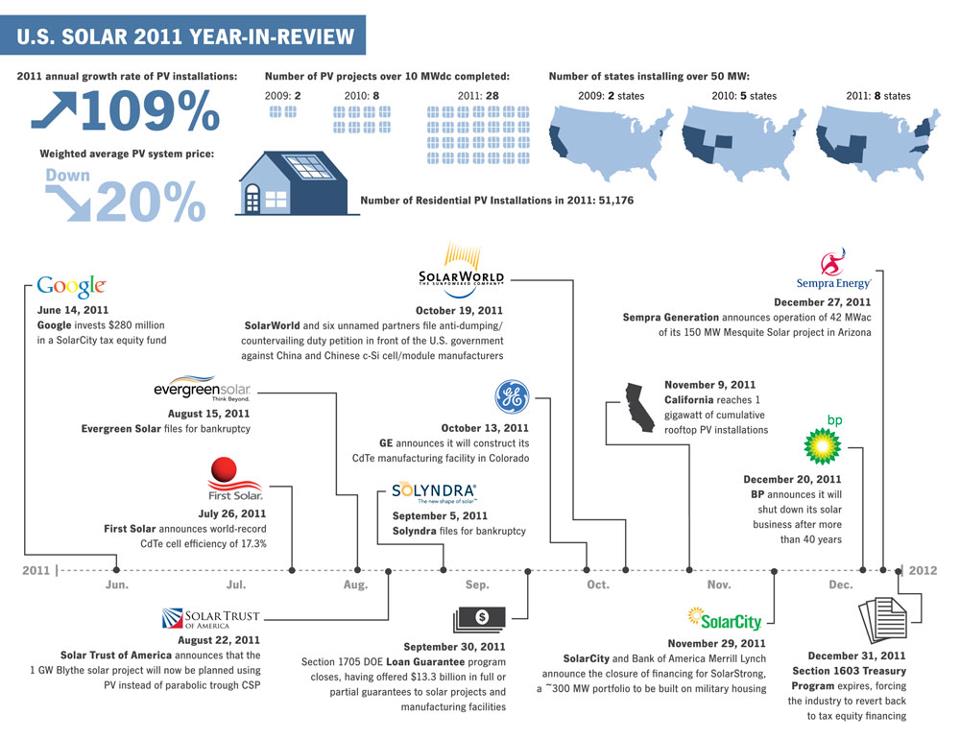

South Coast Solar customer Techcrane, which manufactures cranes used in offshore drilling, recently installed a $199,000 system, 30 percent of which was paid for with a 1603 U.S. Treasury Grant and a USDA grant paid for 25 percent. Also tipping the scale in the companies favor was its utility company’s policy for scaling electric bills based on the highest 15-minute demand. Oman explained that the company could now plan its peak consumption operations on the sunniest days to drive down its annual operating costs. Now Techcrane’s rooftop is covered by 184, 228-watt solar modules, which are expected to pay for themselves within five years, Oman said.

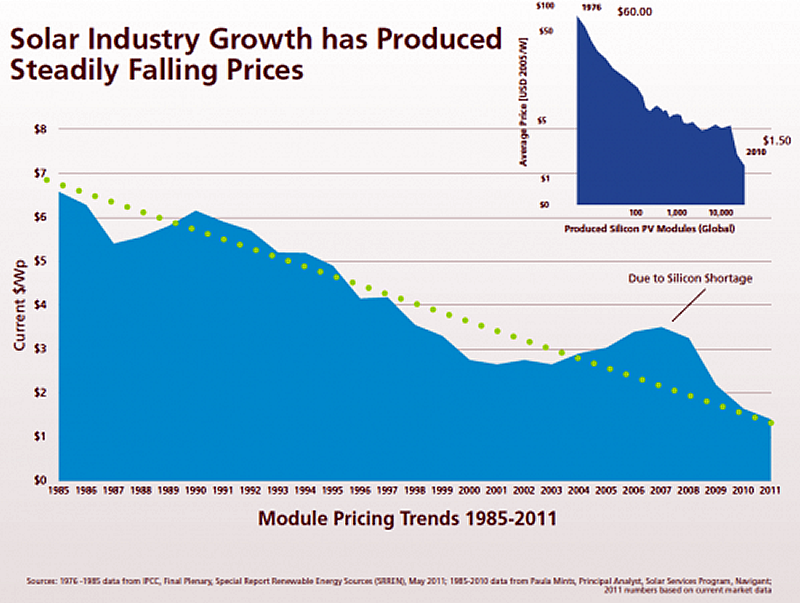

"The tax credits actually are doing their job," South Coast Solar Vice President of Commercial Projects Jerry Hymel said. It has increased competition to drive prices down for both installation and procurement. The refining capabilities of the primary raw material silicon have increased. He said the cost for the end user now is approximately $3.50 per watt to install a panel, which represents a 50 percent decrease from five years ago. Soon the tax incentives will no longer be needed to make solar panels viable solutions.

In fact, solar technology is beginning to look more like a money-making endeavor. Solar power systems often tie directly into the power grid, and excess electricity is fed back to the utility company in exchange for credits. Other systems rely on battery storage, but this is more expensive and Oman recommended investing in the technology that actually generates energy.

"We are not just selling solar panels, in a way we are selling electricity, and you are going to have to buy that energy anyways," Oman said. "We are essentially putting small power plants on rooftops all over the place."

These mini plants help reduce the burden for power companies. In turn, manufacturers will maintain the advantage because it pays to be self reliant. Oman said companies now could exist on their own micro grids. And when a catastrophe like Hurricane Sandy severs power for extended periods, manufacturers can keep making money.